Summary: Controllix Corporation transitioned a coastal utility from using open rack style capacitor banks to their advanced metal-enclosed capacitor banks. This change notably improve...

Summary: Controllix Corporation transitioned a coastal utility from using open rack style capacitor banks to their advanced metal-enclosed capacitor banks. This change notably improve...Metal Enclosed vs. Rack-Mounted Capacitor Banks

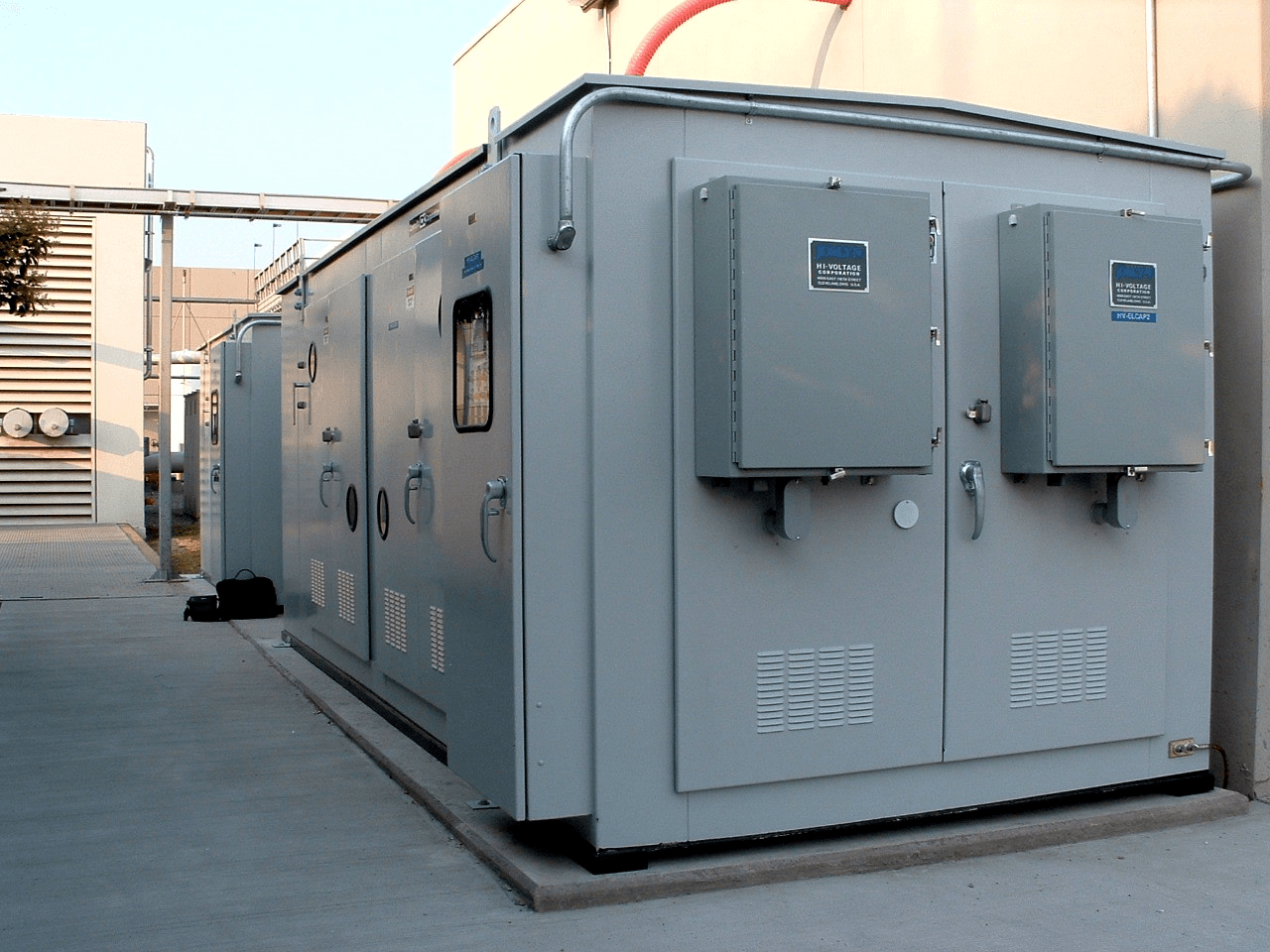

A Metal-Enclosed Bank comes fully assembled, tested, and ready for interconnection. No field assembly is required. Therefore installation costs and problems associated with mistakes during installation are very low.

Maintenance costs for Metal-Enclosed Banks are low. Special equipment such as bucket trucks and hot-line tools, as well as trained personnel necessary to utilize them, are not required due to the construction and controls features that are provided with Metal-Enclosed Banks.

A Metal-Enclosed Bank significantly reduces the risks and the associated liability of trespassing or tampering public and untrained employees becoming exposed to electrical hazards. With Metal Enclosed banks, all live parts are contained in a grounded, key-interlocked enclosure and no external hardware is accessible.

Pad Mounted Banks do not need to be located within a fenced-in substation.

Metal-Enclosed Banks and Pad-Mounted Banks have a small footprint.

Wildlife and air-born settlements that can cause faults and insulator tracking do not readily affect Metal-Enclosed Banks.

Metal Enclosed Banks provide good corrosion resistance to all electrical components as they are protected by an 11-guage galvaneal enclosure that is painted with a Marine Epoxy-Based Paint. This paint provides excellent chemical resistance to splash, spillage, fumes, and weather for acidic, alkaline, salt solutions (acid, neutral, and alkaline salt solutions), fresh water, solvents, and petroleum product environments.

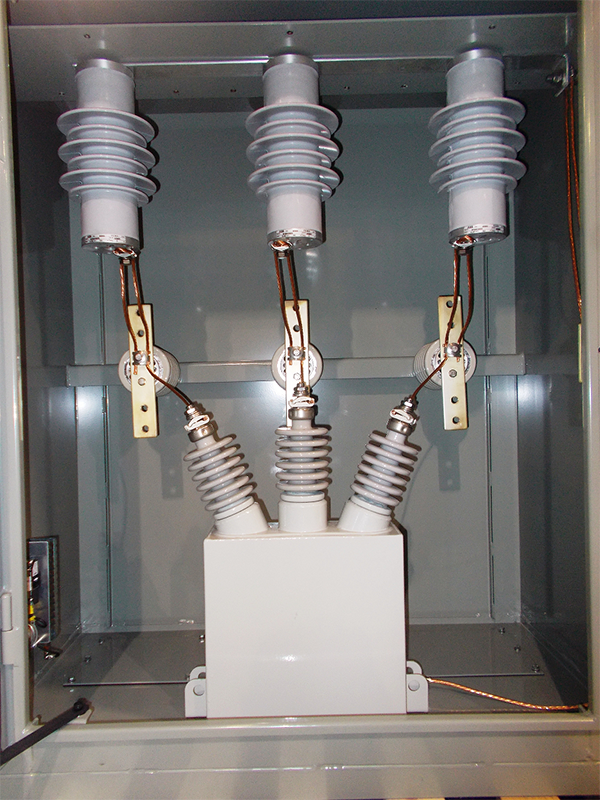

Metal-Enclosed Banks utilize current limiting fuses that dramatically reduce damage associated with faults. Current limiting fuses also provide for the best coordination with upstream protective devices and therefore reduce the liability associated with a system-wide power outage.

Metal-Enclosed Banks are aesthetically pleasing due to their low profile and small footprint. In addition, they can be painted to match the surrounding architecture.

Components within Metal-Enclosed Banks are shaded from direct sunlight and Ultra-Violet rays.

The Main-Incoming Switch, Ground Switch, and Main Incoming Fuses meet the NEC requirements for “Service Entrance Gear”. An interposing or upstream breaker or switch is not required to connect this type of bank to an electric utility service point.

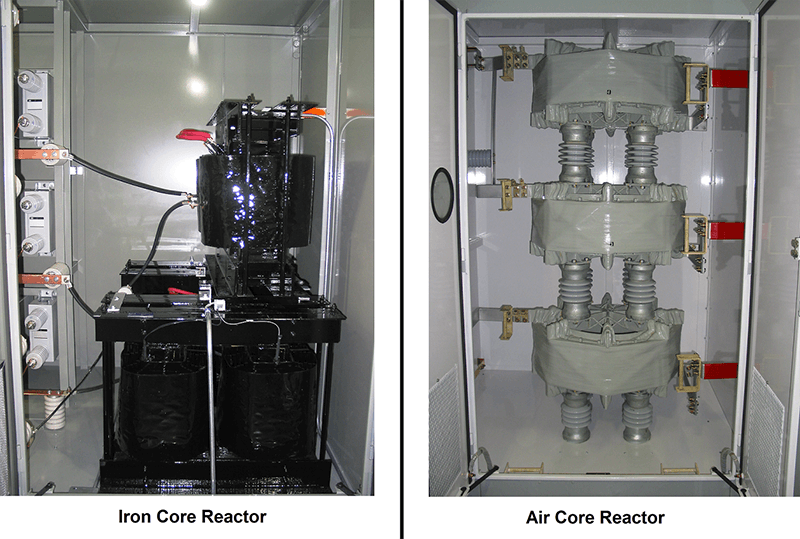

For filter banks, the magnetic field associated with the filter reactors will be confined to the iron-core.