Summary: Controllix Corporation transitioned a coastal utility from using open rack style capacitor banks to their advanced metal-enclosed capacitor banks. This change notably improve...

Summary: Controllix Corporation transitioned a coastal utility from using open rack style capacitor banks to their advanced metal-enclosed capacitor banks. This change notably improve...Controllix Fortifies a Coastal Utility with Metal Enclosed Capacitor Banks

Summary: Controllix Corporation transitioned a coastal utility from using open rack style capacitor banks to their advanced metal-enclosed capacitor banks. This change notably improved the utility’s resilience against weather-related events such as hurricanes and reduced wildlife interference. The metal-enclosed design also incorporated key interlocking features, enhancing safety measures for maintenance personnel.

Industry: Utilities/Energy

Category: Equipment Upgrade

Processes: Welding Fully Enclosed Metal Structures, Incorporating Key Interlocking Mechanisms, Designing for Resilient Electrical Integration

The coastal utility customer faced ongoing challenges related to their open rack style capacitor banks. Their geographic location exposed them to extreme weather conditions, including hurricanes, which put their equipment at risk. Additionally, the absence of a protective enclosure made the system vulnerable to interference from local wildlife. Another critical issue was the lack of safety features, posing risks to maintenance personnel.

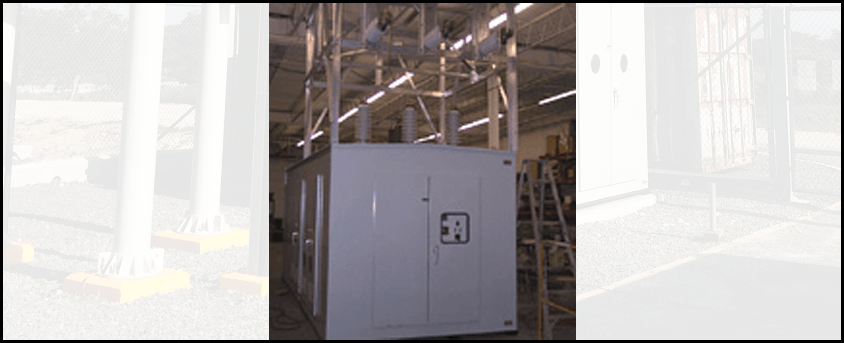

To directly address these challenges, Controllix Corporation provided the utility with our metal-enclosed capacitor banks. Unlike the open rack style, these come with a fully welded metal enclosure designed to protect the equipment from weather-related events and wildlife. This added layer of protection significantly minimizes risks and ensures a more reliable operation.

Additionally, the metal-enclosed design includes key interlocking mechanisms to secure the safety of maintenance personnel, alleviating concerns about workplace hazards during both routine and emergency maintenance.

With the implementation of Controllix Corporation’s metal-enclosed capacitor banks, the coastal utility has experienced meaningful improvements in key operational areas. The enhanced resilience against severe weather conditions, particularly hurricanes, has offered the utility a higher degree of confidence in the reliability of their electrical supply infrastructure. Additionally, the incidence of interference from local wildlife has been notably reduced. Moreover, the safety conditions for maintenance personnel have been substantially improved through the integrated key interlocking mechanisms. These benefits together contribute to a more secure and reliable utility operation.