Summary: Controllix Corporation transitioned a coastal utility from using open rack style capacitor banks to their advanced metal-enclosed capacitor banks. This change notably improve...

Summary: Controllix Corporation transitioned a coastal utility from using open rack style capacitor banks to their advanced metal-enclosed capacitor banks. This change notably improve...Transforming a New England Substation with Controllix’s Metal-Enclosed Capacitor Banks

Summary: A major New England utility facing voltage instability and stringent local permitting requirements found a reliable, space-efficient solution with Controllix Corporation’s metal-enclosed capacitor banks. The design met all operational needs and local guidelines while requiring significantly less space than a conventional open-rack design. Enhanced with features like a safety interlock system, good corrosion resistance, and UV shielding, the new equipment not only met but exceeded the utility’s operational and safety expectations.

Industry: Utilities/Energy

Category: Substation Equipment Upgrade

Processes: Component Integration, Metal Enclosure Fabrication, Safety Interlock Implementation, Beam and Tie Foundation Use, Microprocessor Control Installation

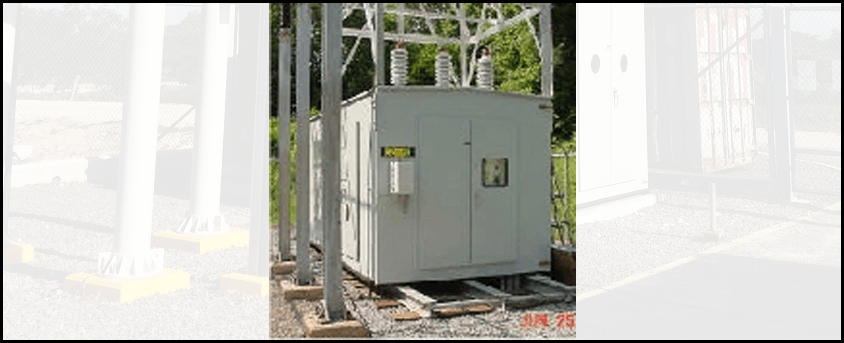

A major New England utility installs capacitor banks at various substations to provide voltage support during normal and contingency operating conditions. In certain conditions at the particular substation, the voltage levels were unacceptable and it was determined that two (2) 46kV, 3600KVAR capacitor banks were required.

Due to local permitting requirements, the existing fence line could not be expanded, no soils could be removed and the visual impact of the new equipment needed to be minimized. The location of the substation and continued need for mobile transformer space indicated that alternate designs were essential.

Conventional capacitor bank designs consist of an open rack with capacitor units mounted within the rack structure. Separate structures and concrete foundations are required for each major component, including the switch, capacitor rack and power fuse assembly. The sensing transformer and series reactors are typically cantilevered off the capacitor rack thereby increasing the width. The typical open-rack design height is 25 feet and requires approximately 500 square feet of space for the bank and associated equipment. Conventional design was not acceptable for this particular substation.

A metal-enclosed capacitor bank was chosen for this substation. The unit includes a 3600KVAR bank, 46kV vacuum switch, reactors, bus and protection equipment. All of the equipment is located in a low-profile enclosure that contains a safety interlock system for personnel safety.

The metal-enclosed design allows the use of a beam and tie foundation, which eliminated the need for concrete foundations and soil removal. The metal enclosed bank is 15 feet high, including the fuses, and requires only 170 square feet of substation space. A microprocessor-based control unit operating on time-of-day, with voltage override controls the bank. The cost of the bank is approximately the same as a conventional open-rack design, considering foundations, structures and cabling requirements.

Metal-enclosed banks provide good corrosion resistance to all electrical components and shield from direct sunlight and ultra-violet rays increasing life expectancy. Metal-enclosed banks significantly reduce the risks and the associated liability of trespassing or tampering, faults due to animals, and are aesthetically pleasing due to their low profile and small footprint.